How to Make a T-shirt with Polyurethane Heat Transfer Film using the Epilog Laser

For a long time, we thought that you could NOT use Heat Transfer Vinyl in the laser, because you can't cut vinyl in a laser. We'd use the vinyl cutter, but some of us prefer using the laser...

Then one day, while looking at the Siser Easyweed product page on the Siser website we had an epiphany - SOME HEAT TRANSFER "VINYL" IS REALLY MADE FROM POLYURETHANE! Woah.

Turns out Epilog was way ahead of us and even had a page on how to use it in the Epilog laser.

This guide was written by Ian Cole, feel free to ask questions or ask for a 1:1 to get started!

Contents

Getting Started

- Watch a livestream of Ian making a custom shirt for an overview of the process

- Look at a Flickr album of things made with this process to get ideas

Materials Used

- Heat Transfer Film - it must be made from POLYURETHANE (PU) NOT VINYL (PVC)

- One example is Siser EasyWeed - you can see from their website product page that it is made from polyurethane

YOU CANNOT CUT STANDARD ADHESIVE VINYL in this manner. USE THE VINYL CUTTER.

Prepping the Art

Create your art for vector cutting (this should link to another wiki page). Using this method, we will use one power/speed setting for cutting weed areas (cutting the film layer but NOT the adhesive backing) and another power/speed setting for cutting all the way through both layers. You can also just use a pair of scissors to cut your item out of a larger sheet instead of using the laser for these cuts.

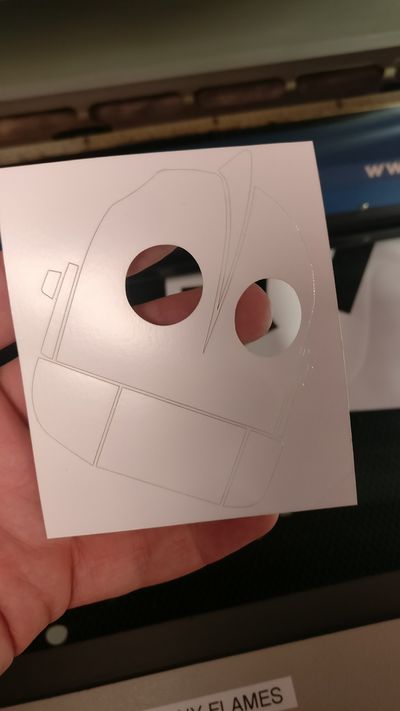

Be careful that you don't have overlapping paths - this is very common when using the illustrator image trace to vectorize art. Double paths will get twice the laser power and cut out small areas... double check your paths carefully. For example, on this art, I accidentally cut out the eyes...oops!

REVERSE THAT ART!

Cutting the Film

- Do something

Weeding the Film

- Tip - weed the smaller pieces before doing the larger pieces. This way the small bits (and your hands) aren't getting stuck to the large exposed adhesive film areas

Heat Transferring the Film

- Set the Heat Press to 305 degrees, and wait 10-15 minutes for it to warm up.

From the Siser EasyWeed product page (see Application Instructions)

Application Instructions (heat press)

- Preheat garment for 2-3 seconds (I haven't been doing this...now I know!)

- Apply design at 305°F/150°C

- Use medium pressure for 10-15 seconds

- Peel carrier hot or cold

Learning Resources

- Links:

- linky

- linky

- linky

- Videos:

- video linky

To Research

- linky

- linky

Related Projects

- linky