Difference between revisions of "Deltamaker 2"

| (51 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

| + | {{MFXReserveToolTime}} | ||

| + | |||

{{Box-round|title=NOTICE!| | {{Box-round|title=NOTICE!| | ||

| − | === PLA only! No PETG or ABS === | + | === PLA only! No PETG or ABS / [https://www.deltamaker.com/collections/filament Local Source for PLA] (Get MakerFX discount code from zone manager) === |

}} | }} | ||

| − | [[File:Deltamaker.jpg|200px| | + | =DeltaMaker Printers at MakerFX= |

| + | The DeltaMaker printers have OctoPrint built-in which includes a built-in slicer. Click any of the printers below to be directed to OctoPrint. | ||

| + | |||

| + | Login as admin with password of 3dadmin to operate the printer. | ||

| + | |||

| + | {| class="wikitable" | ||

| + | |||

| + | |- | ||

| + | | style="vertical-align:top; text-align:center; background-color: #E5E7E9;" | | ||

| + | === [http://192.168.1.98 deltamaker-0197] === | ||

| + | | style="vertical-align:top; text-align:center; background-color: #E5E7E9;" | | ||

| + | === [http://192.168.1.204 deltamaker-0187] === | ||

| + | | style="vertical-align:top; text-align:center; background-color: #E5E7E9;" | | ||

| + | === [http://192.168.1.202 deltamaker-0168] === | ||

| + | |||

| + | |- | ||

| + | | [[File:Deltamaker.jpg|200px|right|link=http://192.168.1.98]] | ||

| + | | [[File:Deltamaker.jpg|200px|right|link=http://192.168.1.204]] | ||

| + | | [[File:Deltamaker.jpg|200px|right|link=http://192.168.1.202]] | ||

| + | |||

| + | |- | ||

| + | | http://192.168.1.98 | ||

| + | | http://192.168.1.204 | ||

| + | | http://192.168.1.202 | ||

| + | |||

| + | |- | ||

| + | | 240mm hexagon x 260 mm | ||

| + | | 240mm hexagon x 260 mm | ||

| + | | 240mm hexagon x 260 mm | ||

| + | |||

| + | |- | ||

| + | | Heated Bed = NO | ||

| + | | Heated Bed = NO | ||

| + | | Heated Bed = NO | ||

| + | |||

| + | |- | ||

| + | | Nozzle = 0.40 | ||

| + | | Nozzle = 0.40 | ||

| + | | Nozzle = 0.40 | ||

| + | |||

| + | |} | ||

| + | |||

| + | |||

| + | =Pre-Flight Instructions= | ||

| + | Once these steps are completed, they do not need to be completed before each and every print in a given session. They only take a few minutes to complete and it will ensure you have a good experience with the printer. | ||

| + | |||

| + | {| class="wikitable" | ||

| + | |||

| + | |- | ||

| + | | style="vertical-align:top; text-align:left; background-color: #E5E7E9;" | Step | ||

| + | | style="vertical-align:top; text-align:left; background-color: #E5E7E9;" | Text Instructions | ||

| + | | style="vertical-align:top; text-align:left; background-color: #E5E7E9;" | Screenshot | ||

| + | |||

| + | |- | ||

| + | | 1 | ||

| + | | [http://things.deltamaker.com/support/DeltaMaker-Getting-Started-Guide.pdf#page=8 Calibration] | ||

| + | |||

| + | A. Under the Control tab, click “Auto Bed Mapping”. | ||

| + | |||

| + | B. This process will take a couple of minutes. You will see the nozzle moving to the bed in several locations around the bed. This is how the printer maps out the bed and knows exactly where it is. | ||

| + | |||

| + | | [[File:Deltamaker-Calibration.jpg|400px|right]] | ||

| + | |||

| + | |- | ||

| + | | 2 | ||

| + | | [http://things.deltamaker.com/support/DeltaMaker-Getting-Started-Guide.pdf#page=9 Setting nozzle height] | ||

| + | |||

| + | A. Place a regular sheet of paper on the printer bed, and select “Move Nozzle to Bed”. | ||

| + | |||

| + | B. After the nozzle is lowered, you should be able to move the paper under the nozzle with a small amount of friction. | ||

| + | |||

| + | C. If you feel no friction, it means the nozzle is too high. Click on “Too High” and retest for friction. | ||

| + | |||

| + | D. If it feels tight or you feel a lot of friction, click on “Too Low”. This will raise the nozzle slightly. | ||

| + | |||

| + | E. Adjust the nozzle until you feel just a small amount of friction between it and the sheet of paper. | ||

| + | |||

| + | F. Remember to click Save & Home when you have the nozzle height adjusted. | ||

| + | |||

| + | | [[File:Deltamaker-SetNozzleHeight.jpg|400px|right]] | ||

| + | |||

| + | |- | ||

| + | | 3 | ||

| + | | [http://things.deltamaker.com/support/DeltaMaker-Getting-Started-Guide.pdf#page=18 Instructions if you need to unload filament] | ||

| + | |||

| + | A. Make sure your DeltaMaker 3D Printer is at temperature (230°C). | ||

| + | |||

| + | B. Grasp the filament directly below the extruder drive, and pinch the trigger. | ||

| + | |||

| + | C. PUSH a few centimeters of filament into the extruder, and observe a string of melted filament exiting the nozzle. | ||

| + | |||

| + | D. Then, SLOWLY PULL the filament out of the extruder, and recoil it on your filament spool. | ||

| + | |||

| + | | [[File:Deltamaker-SetNozzleTemp.jpg|400px|right]] | ||

| + | |||

| + | |- | ||

| + | | 4 | ||

| + | | [http://things.deltamaker.com/support/DeltaMaker-Getting-Started-Guide.pdf#page=10 Loading filament] | ||

| + | A. Under the Temperature tab, select 230 degrees C from dropdown box for the hot end labeled | ||

| + | “set”. The nozzle gets VERY HOT. Always use snips, pliers or other tools when removing scraps of | ||

| + | PLA from the nozzle. | ||

| − | + | B. Snip at a slight angle the end of the spool of PLA (about .5” from the end or past any sharp kinks). | |

| + | |||

| + | C. Straighten the first six inches of the PLA by gently bending it. | ||

| + | |||

| + | D. Slip the end of the PLA through the hole in the trigger. | ||

| + | |||

| + | E. Squeeze the trigger and push the PLA up into the Bowden (clear) tube. Getting it past the opening may require turning the PLA or adjusting hand position. | ||

| + | |||

| + | F. Once past the opening, you should be able to see the PLA going through the tube toward the | ||

| + | extruder. You will feel the PLA stop, but you aren’t quite there just yet. Keep feeding the PLA | ||

| + | while squeezing the trigger. | ||

| + | |||

| + | G. Slowly and easily push the PLA past the resistance point at the end of the tube. You should be | ||

| + | able to feel it give way and then see PLA flowing from the print head. | ||

| + | |||

| + | | [[File:Deltamaker-SetNozzleTemp.jpg|400px|right]] | ||

| + | |||

| + | |- | ||

| + | | 5 | ||

| + | | [http://things.deltamaker.com/support/DeltaMaker-Getting-Started-Guide.pdf#page=15 Preparing to print] | ||

| + | | | ||

| + | |||

| + | |} | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

=Consumables= | =Consumables= | ||

| − | |||

*Tape | *Tape | ||

| − | * | + | *Sandpaper (80 grit) |

*Purple Disappearing Glue Stick | *Purple Disappearing Glue Stick | ||

| + | |||

| + | |||

| + | =Information= | ||

| + | *[http://things.deltamaker.com/support/DeltaMaker-Getting-Started-Guide.pdf DeltaMaker Getting Started Guide] | ||

| + | *[https://deltamaker.freshdesk.com/support/home DeltaMaker Support / Knowledgebase] | ||

| + | |||

=Maintenance= | =Maintenance= | ||

| + | *[https://deltamaker.freshdesk.com/support/solutions/articles/6000046437-build-plate-maintenance Build Plate Maintenance] | ||

*[[Deltamaker 2-One Routine Maintenance|Routine Maintenance]] | *[[Deltamaker 2-One Routine Maintenance|Routine Maintenance]] | ||

*[[Deltamaker 2-One Maintenance Log|Maintenance Log]] | *[[Deltamaker 2-One Maintenance Log|Maintenance Log]] | ||

Latest revision as of 09:25, 30 September 2018

REMEMBER To Reserve Time!

Various tools such as the lasers, 3D Printers, and Forest CNC need to be reserved before using the tool. There is a link on each tool's wiki page, and in each tool's Slack channel to reserve time, or you can select the tool from the MakerFX PickTime page

Note: As of March 2025, we are implementing PickTime tool by tool - review the Slack channel for each tool for current status.

NOTICE!

PLA only! No PETG or ABS / Local Source for PLA (Get MakerFX discount code from zone manager)

DeltaMaker Printers at MakerFX

The DeltaMaker printers have OctoPrint built-in which includes a built-in slicer. Click any of the printers below to be directed to OctoPrint.

Login as admin with password of 3dadmin to operate the printer.

deltamaker-0197 |

deltamaker-0187 |

deltamaker-0168 |

| http://192.168.1.98 | http://192.168.1.204 | http://192.168.1.202 |

| 240mm hexagon x 260 mm | 240mm hexagon x 260 mm | 240mm hexagon x 260 mm |

| Heated Bed = NO | Heated Bed = NO | Heated Bed = NO |

| Nozzle = 0.40 | Nozzle = 0.40 | Nozzle = 0.40 |

Pre-Flight Instructions

Once these steps are completed, they do not need to be completed before each and every print in a given session. They only take a few minutes to complete and it will ensure you have a good experience with the printer.

| Step | Text Instructions | Screenshot |

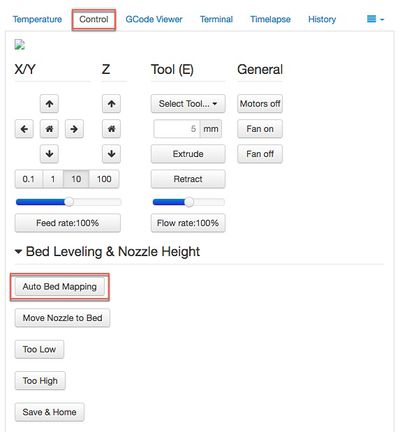

| 1 | Calibration

A. Under the Control tab, click “Auto Bed Mapping”. B. This process will take a couple of minutes. You will see the nozzle moving to the bed in several locations around the bed. This is how the printer maps out the bed and knows exactly where it is. |

|

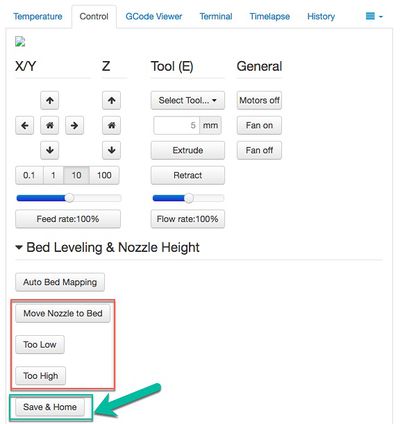

| 2 | Setting nozzle height

A. Place a regular sheet of paper on the printer bed, and select “Move Nozzle to Bed”. B. After the nozzle is lowered, you should be able to move the paper under the nozzle with a small amount of friction. C. If you feel no friction, it means the nozzle is too high. Click on “Too High” and retest for friction. D. If it feels tight or you feel a lot of friction, click on “Too Low”. This will raise the nozzle slightly. E. Adjust the nozzle until you feel just a small amount of friction between it and the sheet of paper. F. Remember to click Save & Home when you have the nozzle height adjusted. |

|

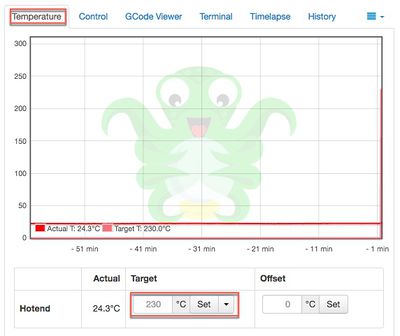

| 3 | Instructions if you need to unload filament

A. Make sure your DeltaMaker 3D Printer is at temperature (230°C). B. Grasp the filament directly below the extruder drive, and pinch the trigger. C. PUSH a few centimeters of filament into the extruder, and observe a string of melted filament exiting the nozzle. D. Then, SLOWLY PULL the filament out of the extruder, and recoil it on your filament spool. |

|

| 4 | Loading filament

A. Under the Temperature tab, select 230 degrees C from dropdown box for the hot end labeled “set”. The nozzle gets VERY HOT. Always use snips, pliers or other tools when removing scraps of PLA from the nozzle. B. Snip at a slight angle the end of the spool of PLA (about .5” from the end or past any sharp kinks). C. Straighten the first six inches of the PLA by gently bending it. D. Slip the end of the PLA through the hole in the trigger. E. Squeeze the trigger and push the PLA up into the Bowden (clear) tube. Getting it past the opening may require turning the PLA or adjusting hand position. F. Once past the opening, you should be able to see the PLA going through the tube toward the extruder. You will feel the PLA stop, but you aren’t quite there just yet. Keep feeding the PLA while squeezing the trigger. G. Slowly and easily push the PLA past the resistance point at the end of the tube. You should be able to feel it give way and then see PLA flowing from the print head. |

|

| 5 | Preparing to print |

Consumables

- Tape

- Sandpaper (80 grit)

- Purple Disappearing Glue Stick

Information