Difference between revisions of "Epilog Legend 36EXT 50 Watt Laser Engraver"

| (5 intermediate revisions by 2 users not shown) | |||

| Line 16: | Line 16: | ||

:Engraving and cutting keychains | :Engraving and cutting keychains | ||

| − | |||

=Policies for the Epilog Legend 36EXT 50 watt Laser Engraver= | =Policies for the Epilog Legend 36EXT 50 watt Laser Engraver= | ||

| Line 22: | Line 21: | ||

=Information= | =Information= | ||

| − | *[https://www.epiloglaser.com/ | + | *[https://www.epiloglaser.com/laser-machines/l36ext-techspecs.htm Epilog Legend 36EXT Technical Specifications] |

*[https://www.epiloglaser.com/downloads/pdf/ext_4.22.10.pdf Epilog Legend 36EXT Manual] - Settings are on page 210 (printed page numbers / 222 (pdf page) | *[https://www.epiloglaser.com/downloads/pdf/ext_4.22.10.pdf Epilog Legend 36EXT Manual] - Settings are on page 210 (printed page numbers / 222 (pdf page) | ||

*[https://www.epiloglaser.com/resources/sample-club/stainless-steel-tumbler.htm Marking Stainless Steel using Cermark] | *[https://www.epiloglaser.com/resources/sample-club/stainless-steel-tumbler.htm Marking Stainless Steel using Cermark] | ||

| Line 37: | Line 36: | ||

*[[Epilog Legend 36EXT 50 watt Laser Engraver Routine Maintenance|Routine Maintenance]] | *[[Epilog Legend 36EXT 50 watt Laser Engraver Routine Maintenance|Routine Maintenance]] | ||

*[[Epilog Legend 36EXT 50 watt Laser Engraver Maintenance Log|Maintenance Log]] | *[[Epilog Legend 36EXT 50 watt Laser Engraver Maintenance Log|Maintenance Log]] | ||

| + | |||

| + | =Troubleshooting= | ||

| + | *Raster engraves are wavy (lines not straight, image appears to drift) - The encoder strip is likely dirty. DO NOT ATTEMPT TO CLEAN. Please contact laser POC or post in slack channel. | ||

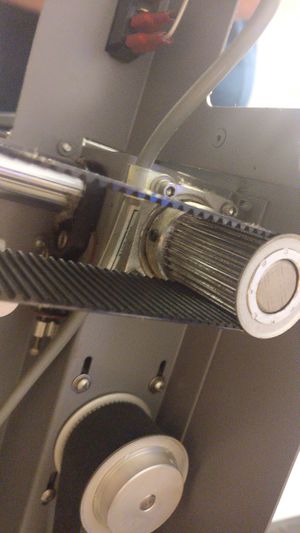

| + | *Y-Axis carriage has play & noise, vector straight lines and some raster are not straight - Y-axis belt pulley at front of machine may have loose set screw. DO NOT ATTEMPT TO FIX. Please contact laser POC or post in slack channel. | ||

| + | [[File:epilog_y-axis_pulley_set_screws.jpg|300px]] | ||

---- | ---- | ||

[[Laser_Zone|Go to the Laser Zone]] | [[Laser_Zone|Go to the Laser Zone]] | ||

[[Report_Dead_Links_Here|Report Dead Links]] | [[Report_Dead_Links_Here|Report Dead Links]] | ||

Latest revision as of 17:31, 29 September 2018

Location: Laser Zone

Point Of Contact @JStutz on Slack or by e-mail at james_stutz@hotmail.com

MakerFX is home to a professional-class Epilog Legend 36EXT 50 watt laser engraver, which engraves and cuts acrylic, wood, paper, and much more. We also have the rotary tool which is great for engraving glasses or stainless steel tumblers. MakerFX membership provides training and use of the laser for prototyping and creative projects.

Want to learn more about laser engraving and cutting, or get started making your own items on the laser? Visit MakerFX for a Friday OpenMake night (info and RSVP on meetup), or email us for more information.

Sample items we’ve made with the Epilog laser

- Laser-engraved keychains

- Cake topper made from two layers of acrylic from hand-drawn art

- Mother’s day present made with scrap red acrylic

- Fidget spinner made with the laser

- Fidget spinner cut on the Epilog Laser

- Engraving and cutting keychains

Contents

Policies for the Epilog Legend 36EXT 50 watt Laser Engraver

Minors can only operate the laser under MakerFX member adult supervision.

Information

- Epilog Legend 36EXT Technical Specifications

- Epilog Legend 36EXT Manual - Settings are on page 210 (printed page numbers / 222 (pdf page)

- Marking Stainless Steel using Cermark

- Epilog Sample Club - Great for ideas on how to use the laser, and includes settings!

- Engraving glasses & mugs with the rotary tool

Videos

Accessories

Consumables

Maintenance

Troubleshooting

- Raster engraves are wavy (lines not straight, image appears to drift) - The encoder strip is likely dirty. DO NOT ATTEMPT TO CLEAN. Please contact laser POC or post in slack channel.

- Y-Axis carriage has play & noise, vector straight lines and some raster are not straight - Y-axis belt pulley at front of machine may have loose set screw. DO NOT ATTEMPT TO FIX. Please contact laser POC or post in slack channel.