Difference between revisions of "VCarveTutorial"

| Line 3: | Line 3: | ||

=Tutorial= | =Tutorial= | ||

| − | This is a very simple tutorial that | + | This is a very simple tutorial will demonstrate how to use the CNC to design a file that will cut two "channels" for t-track from a piece of lumber, from creating a new VCarve file through preparing the GCode for the CNC to use. This tutorial is broken down into the following sections: |

* Creating a new VCarve Job | * Creating a new VCarve Job | ||

* Drawing your designs | * Drawing your designs | ||

* Creating the Toolpaths | * Creating the Toolpaths | ||

* Saving your GCode | * Saving your GCode | ||

| + | |||

| + | |||

== Creating a new VCarve Job == | == Creating a new VCarve Job == | ||

| + | This step is very straight forward and is like creating a new file in any software program you might be familiar with. The critical part of this step is properly setting the dimensions of the material you will be milling. | ||

| + | '''<span style="color:red">NOTE: Failing to properly set the dimensions of your material could result in damage to your project, the bit or to the machine!!!</span>''' | ||

| + | |||

# Open VCarve using the shortcut on the desktop | # Open VCarve using the shortcut on the desktop | ||

# Either open an existing model, or create a new one. For this tutorial, we'll create a new one. | # Either open an existing model, or create a new one. For this tutorial, we'll create a new one. | ||

| Line 23: | Line 28: | ||

== Drawing your designs == | == Drawing your designs == | ||

| + | Once your file has been created, it is time to start your drawing. For this tutorial, we need to carve two grooves into the wood for t-track. The t-track is 12.446 mm deep and 18.542 mm wide. VCarve provides a variety of tools to draw and modify shapes. To draw our grooves, we'll: | ||

| + | # Start by selecting the '''Rectangle Vector''' tool | ||

| + | #:[[File:XCarveRectangle.png]] | ||

| + | # Next, draw a rectangle anywhere on the drawing that represent where we want the grooves to be milled. The placement or size doesn't matter in this step. | ||

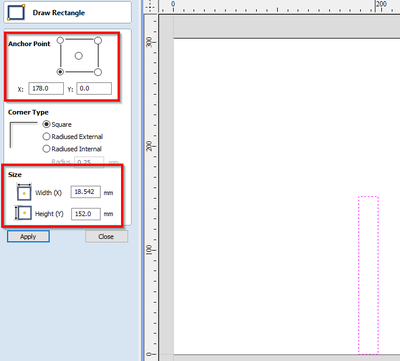

| + | # To accurately size and place the grooves, we can use the fields in the ''Draw Rectangle'' panel. | ||

| + | #* The X and Y values at the top under the ''Anchor Point'' setting allows you to set the X and Y position of the object. In this case, we want the object to be about 1/4 of the way from the left edge and bottom aligned. Since the Anchor Point is set to the lower left corner, to achieve this we need to go in 178 mm on the X axis and 0 for the Y axis. | ||

| + | #* The size of the groove can be set using the ''Size'' settings, specifically the '''Width (X)''' and '''Height (Y)'' fields. The width of the t-track is 18.542 mm and we want to run 1/2 way down the wood, or 152 mm. | ||

| + | #:[[File:XCarveDrawRectangle.png|400px]] | ||

| + | # Once finished, hit the '''Create''' button to draw your object. | ||

| + | # Create another rectangle of the same dimensions, but for this one, set the X / Y coordinates to 535 and 0 to have the second track about 1/4 way in from the other side of the material. | ||

| + | |||

== Creating the Toolpaths == | == Creating the Toolpaths == | ||

| + | |||

| + | |||

== Saving your GCode == | == Saving your GCode == | ||

Revision as of 16:31, 25 July 2017

Contents

Overview

VCarve is one of the many tools you can use to create designs for the X-Carve CNC. MakerFX has a fully functional Makerspace edition of VCarve Pro on the CNC controller computer which is available for members for use. To learn more about VCarve, visit their website.

Tutorial

This is a very simple tutorial will demonstrate how to use the CNC to design a file that will cut two "channels" for t-track from a piece of lumber, from creating a new VCarve file through preparing the GCode for the CNC to use. This tutorial is broken down into the following sections:

- Creating a new VCarve Job

- Drawing your designs

- Creating the Toolpaths

- Saving your GCode

Creating a new VCarve Job

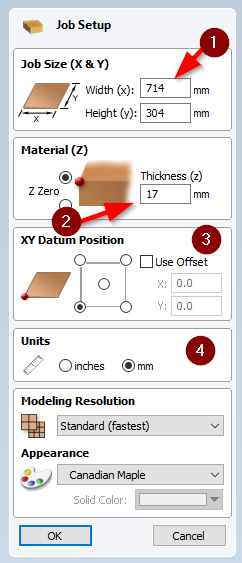

This step is very straight forward and is like creating a new file in any software program you might be familiar with. The critical part of this step is properly setting the dimensions of the material you will be milling. NOTE: Failing to properly set the dimensions of your material could result in damage to your project, the bit or to the machine!!!

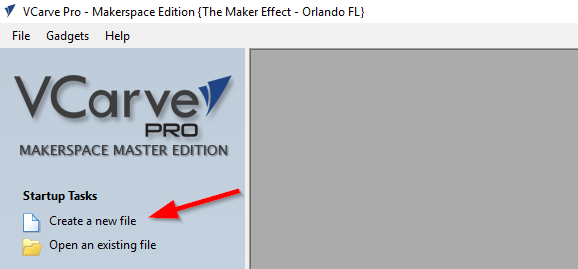

- Open VCarve using the shortcut on the desktop

- Either open an existing model, or create a new one. For this tutorial, we'll create a new one.

- From the JOB SETUP panel, you need to enter the details of the material you'll be using. The image below shows the most important settings:

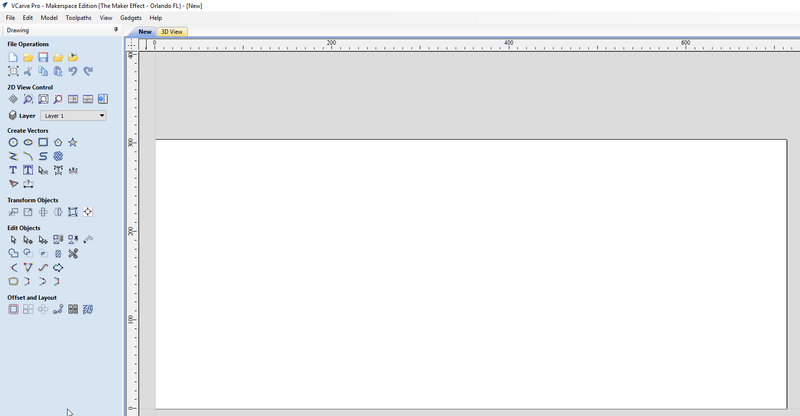

- When you are done setting up your job, click the OK button. The Job Setup panel will close and you will be shown a blank VCarve design screen.

Drawing your designs

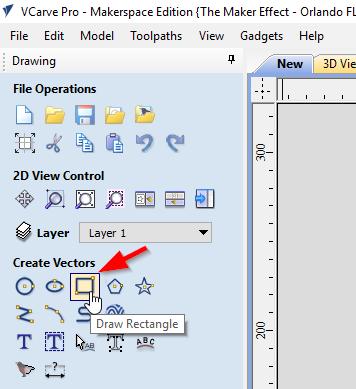

Once your file has been created, it is time to start your drawing. For this tutorial, we need to carve two grooves into the wood for t-track. The t-track is 12.446 mm deep and 18.542 mm wide. VCarve provides a variety of tools to draw and modify shapes. To draw our grooves, we'll:

- Start by selecting the Rectangle Vector tool

- Next, draw a rectangle anywhere on the drawing that represent where we want the grooves to be milled. The placement or size doesn't matter in this step.

- To accurately size and place the grooves, we can use the fields in the Draw Rectangle panel.

- The X and Y values at the top under the Anchor Point setting allows you to set the X and Y position of the object. In this case, we want the object to be about 1/4 of the way from the left edge and bottom aligned. Since the Anchor Point is set to the lower left corner, to achieve this we need to go in 178 mm on the X axis and 0 for the Y axis.

- The size of the groove can be set using the Size settings, specifically the Width (X)' and Height (Y) fields. The width of the t-track is 18.542 mm and we want to run 1/2 way down the wood, or 152 mm.

- Once finished, hit the Create button to draw your object.

- Create another rectangle of the same dimensions, but for this one, set the X / Y coordinates to 535 and 0 to have the second track about 1/4 way in from the other side of the material.