Difference between revisions of "Chevy Volt Battery Documentation"

(→Teardown) |

(→Teardown) |

||

| Line 18: | Line 18: | ||

*[https://www.youtube.com/watch?v=00tTckGUv7I Dissecting the Chevy Volt's electric drivetrain] Shows removing the case and removing the modules | *[https://www.youtube.com/watch?v=00tTckGUv7I Dissecting the Chevy Volt's electric drivetrain] Shows removing the case and removing the modules | ||

*[http://www.schultzengineering.us/delta-11-12.htm This guy took a bandsaw to his Volt modules to remove the cooling portion of the packs.] Don't do this :) | *[http://www.schultzengineering.us/delta-11-12.htm This guy took a bandsaw to his Volt modules to remove the cooling portion of the packs.] Don't do this :) | ||

| + | |||

| + | Tools we used | ||

| + | *Plastic sheeting, Bucket, Rags - there is residual coolant. Not much, but it gets everywhere. Drain at each opportunity | ||

| + | *10mm nut driver on a cordless impact driver - The deeper the better | ||

| + | *10mm socket on a socket wrench and on the cordless impact driver - for the places the nut driver wasn't deep enough | ||

| + | *Prying screwdriver | ||

| + | *Knife - sliced the short coolant hoses, and the tape that holds the battery modules down on the side with the mounting bolts | ||

| + | *Duct Tape - taped the covers so that we'd know where to cut them with the bandsaw | ||

| + | *Bandsaw - cut the covers so that we could move each battery module with a cover on it | ||

| + | *Parts tray - lots and lots of bolts & nuts come off the battery assembly | ||

| + | *Sharpie - Label all the things | ||

| + | *Solid wire - to bind the modules together after removing the rods that hold multiple modules together. You might want to have threaded rod ready, but this worked. | ||

| + | *Big pliers - for twisting the wire to compress the modules after removing the rods | ||

| + | *Gloves - Reduce shock hazard (maybe) and helps with residual coolant and sharp edges. | ||

| + | |||

| + | You might consider | ||

| + | *Non conductive tape, or other material to cover the pack bus bars while the top covers are off. I had a really hard time remembering to NOT touch the top of the pack while the covers were off. | ||

Teardown notes to review before jumping in | Teardown notes to review before jumping in | ||

Revision as of 06:38, 12 November 2017

Contents

Overview

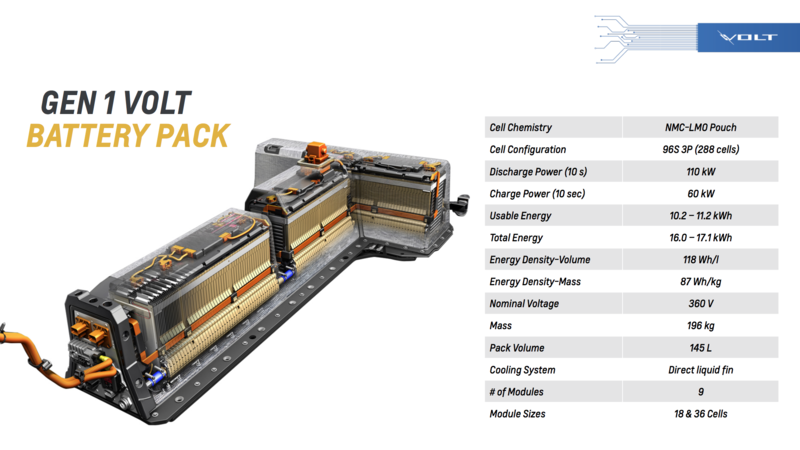

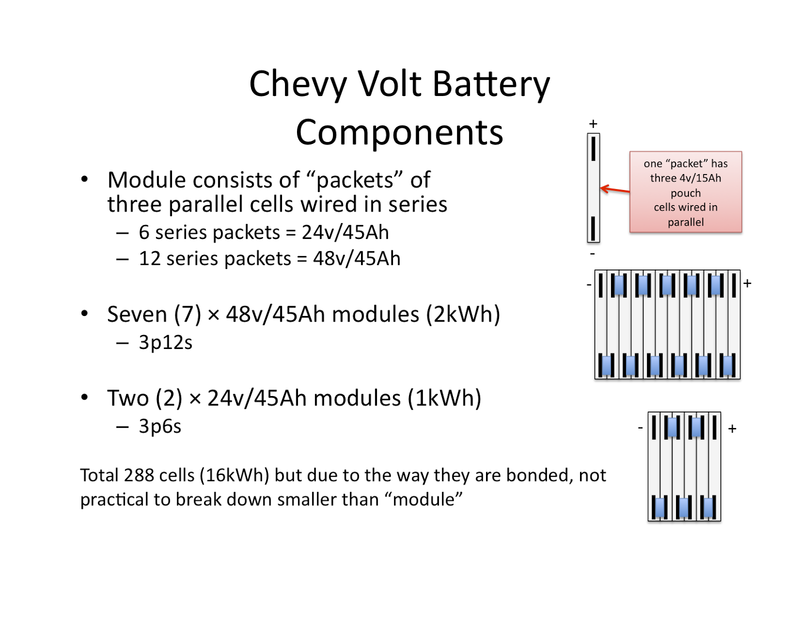

We purchased a Chevy Volt Battery (Gen 1) for $999 from M&K Auto Parts in Orange City, Fl on November 6, 2017. This battery will be torn down to individual modules to be used for new Power Racing Series vehicles for the 2018 season. We are expecting to get seven 48v modules, and two 24v modules from the Volt battery. These modules are heavy (~50 pounds), but should have enough power to not require a battery swap for any race including the 90 minute endurance race.

The 48v modules will be 12s3p configuration.

Battery Information

Teardown

- Dissecting the Chevy Volt's electric drivetrain Shows removing the case and removing the modules

- This guy took a bandsaw to his Volt modules to remove the cooling portion of the packs. Don't do this :)

Tools we used

- Plastic sheeting, Bucket, Rags - there is residual coolant. Not much, but it gets everywhere. Drain at each opportunity

- 10mm nut driver on a cordless impact driver - The deeper the better

- 10mm socket on a socket wrench and on the cordless impact driver - for the places the nut driver wasn't deep enough

- Prying screwdriver

- Knife - sliced the short coolant hoses, and the tape that holds the battery modules down on the side with the mounting bolts

- Duct Tape - taped the covers so that we'd know where to cut them with the bandsaw

- Bandsaw - cut the covers so that we could move each battery module with a cover on it

- Parts tray - lots and lots of bolts & nuts come off the battery assembly

- Sharpie - Label all the things

- Solid wire - to bind the modules together after removing the rods that hold multiple modules together. You might want to have threaded rod ready, but this worked.

- Big pliers - for twisting the wire to compress the modules after removing the rods

- Gloves - Reduce shock hazard (maybe) and helps with residual coolant and sharp edges.

You might consider

- Non conductive tape, or other material to cover the pack bus bars while the top covers are off. I had a really hard time remembering to NOT touch the top of the pack while the covers were off.

Teardown notes to review before jumping in

- LOTS OF HOT POINTS. BE CAREFUL

- Label the BMS modules with each pack - they differ

OEM Battery Management System

- Chevy Volt teardown: The battery pack This video has some great slides showing locations of components and how cells are grouped into packs and then grouped into modules and then detailed info on the BMS. Alternate recording, may have better audio

- Opening a VOLT BMS pack - Note: this is really the individual "Battery Interface Module".

- Adding an aftermarket BMS to a Volt module - Used in an electric Porsche 914

- Thread with CAN BUS logs and lots of other info

- Hall Effect Sensor datasheet (need to confirm model, but found this in a teardown thread

Charging PPPRS 48v Modules

We are unsure how we will charge. We've seen reference to splitting the pack in two electrically to charge as two 6s batteries, and we've also seen where people simply charge the entire pack with voltage monitoring. This is a BIG TODO.

Examples of Volt Battery Usage

- Battery notes on Taylor Dunn re-power with Chevy Volt Lithium batteries - Nice clean fuse mount on the module early in the video

- Lithium-Ion Batteries for Off-Grid Systems Using the Volt battery for a 1kw solar system