CNC Router FAQ

This page attempts to collect commonly asked questions and their answers into one place. It also includes unasked questions that should be asked to hopefully provide insight into the process.

Why is my design have such a long cut time?

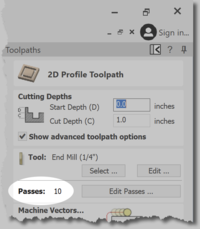

| The most common reason for this issue is not using the proper bit or bit settings. By default VCarvePro starts with very shallow cuts with the "default". You can see in the pictures how to quickly determine if this is the case. First look at the name of the cutting tool. Does it have a name or just a generic name? If it has a generic name, that means that a bit has been taken from the basic system. Typically bit names will have manufacturer and model number. Check out the House Bit page for more information about what bits MakerFx has that you can use. | |

| Another way to tell is if the number of passes is higher than expected. Most of the bits MakerFX has as house bits can cut 3/8" or 1/4" per pass. That means cutting through a 1 inch think material should be done in four passes or less. Having a number such as ten, means that the pass depth might be lower than expected. |

When is the next certification scheduled for?

We have changed our certification process. The complete information is at the CNC Router Training & Certification page in the wiki. The basic overview, is you obtain a license for VCarvePro, study on your own to create a test file, submit the test file when you request a time on the scheduling form.

What are the key items to pay attention to when preparing for certification?

That is quite a wise question. The purpose of certification is to keep you and the equipment safe. Here are some common stumbling points

- Not submitting the file with enough time for the examiner to review and you to make changes.

- Not reading messages on the screen

- Not refering back to either printed documentation or this wiki

- Not loading in the MakerFX house bits

- Remembering that there is a time limit. One is limited to one hour, too much discussion means not enough time to work

- The design does not need to be complicated

- The certification file is designed to show the most common tool paths being used and how to create them

- Literally it could be a circle

- The certification file is designed to insure that you know how to create cutting or tooling paths, not that you are an amazing designer

- We do not try to fail people, we want to make sure you are safe and using the tools properly

- It is open book, open Internet, use Slack ... etc.

From experience we recommend not relying on the certification examiner exclusively. We have found that too much help from the proctor results in frustration during the first solo cut. We want you to succeed and have fun. Asking questions is encouraged, especially on Slack. (That is where the questions come from.)