Difference between revisions of "Wood Zone"

(→Equipment) |

|||

| (22 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

| − | + | {{Box-round|title=General Policies| | |

| − | |||

| − | =General Policies | ||

* Don't place anything wet such as cold drinks or sweaty hands on cast iron surfaces. This causes them to rust. | * Don't place anything wet such as cold drinks or sweaty hands on cast iron surfaces. This causes them to rust. | ||

* No Metal Cutting, this is non negotiable Do not cut any metal, especially ferrous metal in the woodshop with the WOOD Specific tools and blades. Keep the metal working to the metal working section please. Metal chips / shavings will ruin others wood working projects. | * No Metal Cutting, this is non negotiable Do not cut any metal, especially ferrous metal in the woodshop with the WOOD Specific tools and blades. Keep the metal working to the metal working section please. Metal chips / shavings will ruin others wood working projects. | ||

| + | }} | ||

| + | |||

| + | [[File:Wood_Zone_Photo.jpg|250px|thumb|right|Wood Zone]] | ||

=Equipment= | =Equipment= | ||

*[[Craftsman 12 inch Bandsaw-Sander|Craftsman 12 inch Bandsaw-Sander]] | *[[Craftsman 12 inch Bandsaw-Sander|Craftsman 12 inch Bandsaw-Sander]] | ||

| − | |||

| − | |||

| − | |||

*[[Dewalt 20 inch Scroll Saw]] | *[[Dewalt 20 inch Scroll Saw]] | ||

| − | |||

| − | |||

*[[Jet AFS-1000B Air Filtration System]] | *[[Jet AFS-1000B Air Filtration System]] | ||

| − | |||

| − | |||

| − | |||

| − | |||

*[[X-Carve 1000mm CNC Router]] | *[[X-Carve 1000mm CNC Router]] | ||

| − | |||

| − | |||

| − | |||

| − | |||

{| class="wikitable" | {| class="wikitable" | ||

|- | |- | ||

| style="vertical-align:top; text-align:left; background-color: #E5E7E9;" | | | style="vertical-align:top; text-align:left; background-color: #E5E7E9;" | | ||

''' | ''' | ||

| − | === [[Sawstop_10_inch_Professional_Cabinet_Saw | SawStop Professional Table Saw ]] === | + | ==== [[Sawstop_10_inch_Professional_Cabinet_Saw | SawStop Professional Table Saw ]] ==== |

''' | ''' | ||

| style="vertical-align:top; text-align:left; background-color: #E5E7E9;" | | | style="vertical-align:top; text-align:left; background-color: #E5E7E9;" | | ||

''' | ''' | ||

| − | === [[Grizzly_G0555LA35_14"_1_HP_Band_Saw | Grizzly Bandsaw ]] === | + | ==== [[Grizzly_G0555LA35_14"_1_HP_Band_Saw | Grizzly Bandsaw ]] ==== |

''' | ''' | ||

| style="vertical-align:top; text-align:left; background-color: #E5E7E9;" | | | style="vertical-align:top; text-align:left; background-color: #E5E7E9;" | | ||

''' | ''' | ||

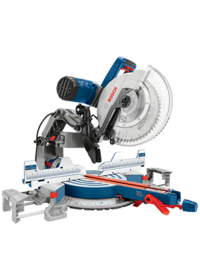

| − | === [[Bosch_12"_Axial_Glide_Compound_Mitre_Saw | Bosch Axial Glide Mitre Saw ]]=== | + | ==== [[Bosch_12"_Axial_Glide_Compound_Mitre_Saw | Bosch Axial Glide Mitre Saw ]]==== |

''' | ''' | ||

| style="vertical-align:top; text-align:left; background-color: #E5E7E9;" | | | style="vertical-align:top; text-align:left; background-color: #E5E7E9;" | | ||

''' | ''' | ||

| − | === DeWalt Thickness Planer === | + | ==== [[Dewalt_735X_Planer | DeWalt Thickness Planer]] ==== |

''' | ''' | ||

|- | |- | ||

| − | | style="height: | + | | style="height:200px; background-color: white;" | |

| − | [[File:SawstopPCS.png| | + | [[File:SawstopPCS.png|200px|center|link=Sawstop_10_inch_Professional_Cabinet_Saw]] |

| − | | style="height: | + | | style="height:200px; background-color: white;" | |

| − | [[File:Grizzly_G0555LA35.jpg| | + | [[File:Grizzly_G0555LA35.jpg|200px|center|link=Grizzly_G0555LA35_14"_1_HP_Band_Saw]] |

| − | | style="height: | + | | style="height:200px; background-color: white;" | |

| − | [[File:Bosch12inchAxialGlide.png| | + | [[File:Bosch12inchAxialGlide.png|200px|center|link=Bosch_12"_Axial_Glide_Compound_Mitre_Saw]] |

| − | | style="height: | + | | style="height:200px; background-color: white;" | |

| − | [[File:Dewalt_DW735X.jpg| | + | [[File:Dewalt_DW735X.jpg|200px|center|link=Dewalt_735X_Planer]] |

|- | |- | ||

| style="vertical-align:top; text-align:left; background-color: #E5E7E9;" | | | style="vertical-align:top; text-align:left; background-color: #E5E7E9;" | | ||

''' | ''' | ||

| − | ===[[Rigid_Oscillating_Edge/Belt_Spindle_Sander | Rigid / | + | ==== [[Rigid_Oscillating_Edge/Belt_Spindle_Sander | Rigid Belt / Spindle Sander]] ==== |

''' | ''' | ||

| style="vertical-align:top; text-align:left; background-color: #E5E7E9;" | | | style="vertical-align:top; text-align:left; background-color: #E5E7E9;" | | ||

''' | ''' | ||

| − | === === | + | |

| + | ==== [[Delta_11-990_Drill_Press | Delta Drill Press]] ==== | ||

''' | ''' | ||

| style="vertical-align:top; text-align:left; background-color: #E5E7E9;" | | | style="vertical-align:top; text-align:left; background-color: #E5E7E9;" | | ||

''' | ''' | ||

| − | === === | + | ==== [[DeWALT_715 | DeWALT 715 Chopsaw]] ==== |

''' | ''' | ||

| style="vertical-align:top; text-align:left; background-color: #E5E7E9;" | | | style="vertical-align:top; text-align:left; background-color: #E5E7E9;" | | ||

''' | ''' | ||

| − | === === | + | ==== [[Delta_52-866X_Jointer | Delta 6" Jointer]] ==== |

''' | ''' | ||

| + | |||

| + | |- | ||

| + | | style="height:200px; background-color: white;" | | ||

| + | [[File:Ridgid-spindle-sanders-eb4424-64_1000.jpg|200px|center|link=Rigid_Oscillating_Edge/Belt_Spindle_Sander]] | ||

| + | |||

| + | | style="height:200px; background-color: white;" | | ||

| + | [[File:Delta 11-990 Drill Press.jpg|200px|center|link=Delta_11-990_Drill_Press]] | ||

| + | |||

| + | | style="height:200px; background-color: white;" | | ||

| + | [[File:Dewalt_DW715.jpg|200px|center|link=Dewalt_DW715]] | ||

| + | |||

| + | | style="height:200px; background-color: white;" | | ||

| + | [[File:Delta_52-866X_Jointer.jpg|200px|center|link=Delta_52-866X_Jointer]] | ||

| + | |||

| + | |- | ||

| + | | style="vertical-align:top; text-align:left; background-color: #E5E7E9;" | | ||

| + | ''' | ||

| + | ==== [[Laguna_C-Flux_Dust_Collector | Laguna C-Flux Dust Collector]] ==== | ||

| + | ''' | ||

| + | |||

| + | | style="vertical-align:top; text-align:left; background-color: #E5E7E9;" | | ||

| + | ''' | ||

| + | ==== [[Fein_Turbo_I_Dust_Extractor | Fein Dust Extractor]] ==== | ||

| + | ''' | ||

| + | |||

| + | | style="vertical-align:top; text-align:left; background-color: #E5E7E9;" | | ||

| + | ''' | ||

| + | ==== [[Oneida_Dust_Deputy | Oneida Dust Deputy]] ==== | ||

| + | ''' | ||

| + | |||

| + | | style="vertical-align:top; text-align:left; background-color: #E5E7E9;" | | ||

| + | ''' | ||

| + | ==== [[Delta_AP_400_Dust_Collector | Delta Dust Collector]] ==== | ||

| + | ''' | ||

| + | |||

| + | |- | ||

| + | | style="height:200px; background-color: white;" | | ||

| + | [[File:Laguna C-Flux Dust Collector.jpg|200px|center|link=Laguna_C-Flux_Dust_Collector]] | ||

| + | |||

| + | | style="height:200px; background-color: white;" | | ||

| + | [[File:Fein_Turbo_I_Shop_Vac.jpg|200px|center|link=Fein_Turbo_I_Dust_Extractor]] | ||

| + | |||

| + | | style="height:200px; background-color: white;" | | ||

| + | [[File:Dust_Deputy.jpg|200px|center|link=Oneida_Dust_Deputy]] | ||

| + | |||

| + | | style="height:200px; background-color: white;" | | ||

| + | [[File:Delta_AP_400_Dust_Collector.jpg|200px|center|link=Delta_AP_400_Dust_Collector]] | ||

Latest revision as of 20:33, 3 February 2021

edit

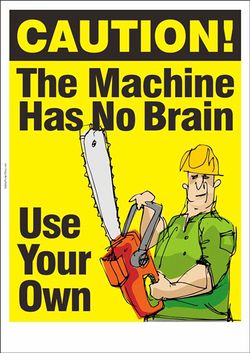

General Policies

- Don't place anything wet such as cold drinks or sweaty hands on cast iron surfaces. This causes them to rust.

- No Metal Cutting, this is non negotiable Do not cut any metal, especially ferrous metal in the woodshop with the WOOD Specific tools and blades. Keep the metal working to the metal working section please. Metal chips / shavings will ruin others wood working projects.

Equipment

- Craftsman 12 inch Bandsaw-Sander

- Dewalt 20 inch Scroll Saw

- Jet AFS-1000B Air Filtration System

- X-Carve 1000mm CNC Router